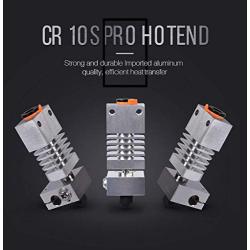

BIGTREETECH Direct MK8 CR10 Extruder Heatsink Upgrade All Metal Hotend with MK8 Nozzle 3D Parts for Ender3 CR10 Heat Breaker

Availability: Pre-Order, Inquiry Price

About this product

*1. 【CR10heatsink hotend】 Strong and durable, imported aluminum quality, efficient heat transfer

*2. 【Suitable for the nozzle:】 MK8 nozzle

*3. 【Fit for filament:】 2 * 4MM

*4. 【Compatible with:】 100K NTC 3950 thermistors

*5. 【Compatible with:】 6 * 20MM heater (If you have any question,please feel free to QA or tell us through Amazon, we will get back to you within 24h, thank you for your support).

Description

?Specification?

Material: aluminum

Suitable for the nozzle: MK8 nozzle

Fit for filament: 2 * 4MM

Compatible with: 100K NTC 3950 thermistors

Compatible with: 6 * 20MM heater

?Friendly Reminder? Recommended setting of the cutting machine: retraction speed over 80 mm / s Retraction length 2.5-4 mm

?Compatible?:

Compatible with CR-10S

Compatible with CR-10S -S5

Compatible with CR-10S -S4

Compatible with CR-10

Compatible with CR-10 -MINI

Compatible with CR-20

Compatible with CR-20 PRO

Compatible with Ender2

Compatible with Ender3

Compatible with Ender3 PRO

Compatible with TronXY X5S

Compatible with Tevo Tornado

Compatible with Alfawise U20

?Recommended slicer setting?:

retraction speed over 80MM/S

retraction length 2.5-4MM

If you are facing PLA clogging problem, please try the followings:

1. Increase the retraction speed. The speed may have being limited in the firmware try to change it. G-command "M203 E200".

2. Increase the extruder acceleration. Check your firmware settings. G-command "M201 E9000".

3. Reduce the retraction length. It depends on your machine setup.

4. Increase the nozzle temperature by 5-10 degrees.

5. Do not install the 2 screws for support the heatblcok like the stock hotend on the CR-10 printer.

6. Make sure that there is no gap between the heatsink and the heat breaker.

![[Gulfcoast Robotics] All Metal V6 Bowden Extruder Hotend for 3D Printer 1.75mm Filament / 0.4mm Nozzle](https://www.metalpartmaker.com/image/cache/catalog/img/41r/41rgSh7o-2BfL-250x250.jpg)

![[Gulfcoast Robotics] All Metal V6 Bowden Extruder Hotend for 3D Printer 1.75mm Filament / 0.4mm Nozzle](https://www.metalpartmaker.com/image/cache/catalog/img/51J/51JUjY-pBDL-250x250.jpg)